For decades, the mining dump truck was considered a symbol of the industrial age. These giant machines, capable of hauling hundreds of tons of ore or overburden, embodied the progress and power of heavy industry. But today, such equipment is increasingly seen as a technological relic. In a world where industrial efficiency now depends on automation, digitalization, and ease of maintenance, bulky dump trucks are losing ground to lighter and smarter cargo transport systems — such as uTrans, based on uST technology.

A modern mining dump truck is a technically complex product that requires tens of tons of steel, high-tech components like transmissions and engines, and special operating conditions. The production of these machines is costly and highly individualized. Their use is limited by high fuel, maintenance, and infrastructure costs, since roads for heavy haulers need constant backfilling, leveling, and repair.

Meanwhile, the efficiency of dump trucks is far from ideal. Even when hauling 300–400 tons of cargo, the engine efficiency rarely exceeds 35%, and the weight of the truck itself is often comparable to the mass of the material being transported. In other words, almost half of all the power generated is spent not on moving useful payload, but on moving the vehicle itself.

Moreover, any malfunction — whether it’s a brake system failure, hydraulic breakdown, or tire blowout — results in downtime that is extremely costly. In the context of a continuous industrial cycle, this becomes a critical factor.

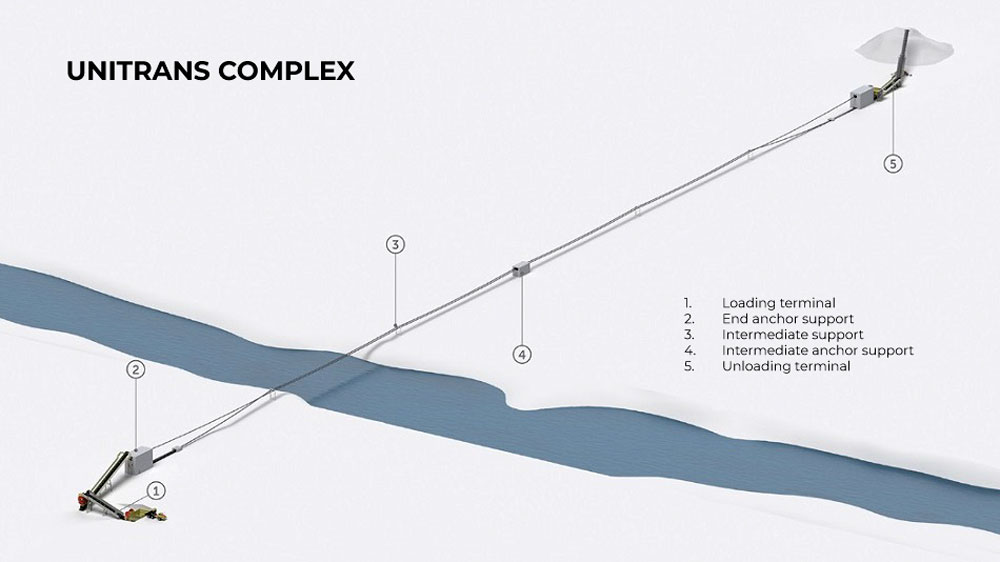

uTrans is an overground automated transport system featuring continuous loop motion, designed for transporting bulk materials without intermediate transshipment. The technology provides throughput of up to 100 million tons per year and operates 24/7.

Instead of traditional half-hour hauling cycles — “mine – crusher – turnaround” — the result is a continuously operating system. Loading and unloading take place on the move, using a conveyor-like principle, but faster, more efficient, and safer.

uTrans is a multi-wheel vehicle that moves along a string rail overpass. The core of the system is a steel rail with tensioned structural elements inside. This design uses a minimal amount of concrete and steel, making the structure lightweight yet capable of handling heavy freight efficiently.

Such an approach eliminates the need to build haul roads or create embankments for heavy machinery. uTrans transports cargo several meters above ground, with minimal rolling resistance and without energy losses from tire friction. An intelligent control system enables continuous conveyor-style delivery of ore, coal, crushed stone, or other raw materials from the mining site to the processing facility.

| Parameter | Mining Dump Truck | uTrans |

| Energy consumption | Internal combustion engine, 1,000–4,000 hp, efficiency ≤ 35% | Electric motor, energy consumption 0.01 kWh/t·km — an order of magnitude lower |

| Infrastructure | Requires haul roads, embankment building, and road maintenance | Minimal land footprint: 3 × 1 m supports, track elevated above ground |

| Reliability | One dump truck = single point of failure | Hundreds of independent modules on a single line |

| Personnel | Dozens of drivers and mechanics required | Full automation |

| Ecology | Emissions and road dust | No emissions, no material dusting |

| Terrain | Limited by gradients | Climbing capability up to 50% |

To operate a single 10-kilometer hauling route with a 15-million-ton annual capacity using dump trucks, even the most conservative estimates indicate the need for 50 four-axle trucks, 150 drivers, and 3 million liters of fuel per year. Operating costs for uTrans allow the same performance at 7–10 times lower expense.

Unlike dump trucks, string rail transport requires no drivers, fuel, or regular suspension replacement. From a capital investment perspective, constructing a uST line is cheaper than building a network of mine haul roads, especially in complex geological or climatic conditions (mountainous terrain, sand, tundra, wetlands). Operating costs are also reduced several-fold.

In addition, the system’s modular design allows easy route adjustments or capacity expansion without dismantling existing infrastructure, which is enough to extend the track or increase the number of autonomous cargo modules.

It is worth noting that this technology has already been tested, refined, and brought to serial-production readiness. A pilot section of the uTrans complex was built in 2018 and is successfully operating at the EcoTechnoPark of UST Inc. in Maryina Gorka (Belarus). The system is designed for hauling granite crushed stone. The line length is 435 meters, and the planned annual throughput is 2 million tons.

String rail lines show particular advantages on long-distance routes, where conventional mining haulage becomes inefficient. uTrans can continuously move cargo over tens of kilometers, including across rough terrain, maintaining a steady transport flow with minimal energy consumption.

The shift from mining dump trucks to string transport systems is not merely a matter of convenience or time savings. It is a strategic direction for heavy industry development, capable of reducing the cost of mineral extraction and processing, improving environmental performance, and enhancing operational safety.

uTrans is not simply a replacement for a dump truck — it is a new transportation paradigm, where cargo moves faster, lighter, and safer, and delivery becomes an integral part of the intelligent infrastructure of the future.

This form asks for your consent to allow us to use your personal data for the reasons stated below. You should only sign it if you want to give us your consent.

Who are we?

The name of the organisation asking you for consent to use your information is:

Global Transport Investments

Trident Chambers, P.O. Box 146, Road Town

Tortola

British Virgin Islands

We would like to use the following information about you:

Why would we like to use your information?

Global Transport Investments would like to send this information to company registry, inform you about its news, for refund purposes.

What will we do with your information?

We store your name, address, ID Data, date of birth into company registry. We will share your e-mail & phone number with IT Service (https://digitalcontact.com/), SMS Center (http://smsc.ru). They will add your details to their mailing list and, when it is news update, they will send you an email or sms with details. We store your credit card number for possible refunds.

How to withdraw your consent

You can withdraw the consent you are giving on this form at any time. You can do this by writing to us at the above address, emailing us at the address: [email protected] or by clicking on the unsubscribe link at the bottom of emails you receive.

This privacy notice tells you about the information we collect from you when you sign up to receive our regular newsletter via our website. In collecting this information, we are acting as a data controller and, by law, we are required to provide you with information about us, about why and how we use your data, and about the rights you have over your data.

Who are we?

We are Global Transport Investments. Our address is Trident Chambers, P.O. Box 146, Road Town, Tortola, British Virgin Islands. You can contact us by post at the above address, by email at [email protected].

We are not required to have a data protection officer, so any enquiries about our use of your personal data should be addressed to the contact details above.

What personal data do we collect?

When you subscribe to our newsletter, we ask you for your name and your email address.

Why do we collect this information?

We will use your information to send you our newsletter, which contains information about our products.

We ask for your consent to do this, and we will only send you our newsletter for as long as you continue to consent.

What will we do with your information?

Your information is stored in our database and is shared with with IT Service (https://digitalcontact.com/), SMS Center (http://smsc.ru). It is not sent outside of the Euro. We will not use the information to make any automated decisions that might affect you.

How long do we keep your information for?

Your information is kept for as long as you continue to consent to receive our newsletter.

Your rights over your information

By law, you can ask us what information we hold about you, and you can ask us to correct it if it is inaccurate.

You can also ask for it to be erased and you can ask for us to give you a copy of the information.

You can also ask us to stop using your information – the simplest way to do this is to withdraw your consent, which you can do at any time, either by clicking the unsubscribe link at the end of any newsletter, or by emailing, writing us using the contact details above.

Your right to complain

If you have a complaint about our use of your information, you can contact the Information Commissioner’s Office.

Rate and Comment

You can assess the importance of a particular publication and the level of its preparation. Share your opinion in the comments!