The creator of string transport has explained why the high-speed technology has been set apart as a distinct area of development and elaborated on the complexity of crafting this advanced transport and infrastructure product.

A series of interviews has been launched where the General Designer at Unitsky String Technologies Inс. answers questions about the unique aspects of working on the creation of string transport.

— Anatoli, why has the high-speed uST technology been allocated as a separate branch? And why does the work completed in this field so far represent only 1% of the total needed to produce this market-ready transport and infrastructure product?

— First, I would like to emphasize that distinguishing the high-speed direction as a separate branch of the uST technology and seeking additional sources of funding for its development pursue two key objectives:

Now let me elaborate on this.

Before the COVID-19 pandemic, we held successful negotiations in several countries regarding land allocation for a 25-kilometer high-speed complex. However, the epidemiological situation disrupted our plans. COVID-19 posed different challenges to governments, diverting their resources to address those pressing issues.

What kind of negotiations can take place when the world plunges into lockdown? On the contrary, during this time, many businesses ceased their operations and even closed down.

However, we demonstrated an entirely different example: we worked hard and not only maintained our activity but also found new development paths. This was largely due to an important strategic decision we made — to narrow the scope of our efforts and focus on tasks that could quickly bring us commercial success. Consequently, this could significantly accelerate the timeline for investor rewards.

We are often criticized for the prolonged negotiations about land allocation. But what can be done if, in most cases, the land belongs to multiple owners and the state?

Imagine this situation: along all 25 kilometers, the land needed for the project is owned by more than a dozen legal entities — agricultural enterprises, farmers, road authorities, railway companies, energy providers, foresters, communication services, and others. How easy do you think it is to negotiate quickly with every single one of them? If even one party says “no,” all our work on the negotiations and preparation of mutually beneficial terms — which often takes years — faces failure.

We even had such an example: over two years, we completed all regional agreements with 16 legal entities, gathering all their signatures and seals. Yet, at the final stage, we received an unexpected refusal. And this happened more than once. Is it still necessary to explain the complexity of the negotiation process?

Additionally, one must consider another point: no one grants a 25-kilometer plot of land for free. Yes, we had a case where land was initially promised to us at no cost. However, this “free” land eventually ended up costing a significant sum, even though entirely different conditions were initially stated, and we were confident of success…

In a previous interview, I mentioned that in one Western European country in 2021, we were close to acquiring land at a favorable cost. However, the subsequent worsening of the geopolitical situation disrupted these plans.

I have often stated that we manage the funds received from investors with the utmost rationality. Due to the prolonged process of searching a 25-kilometer land plot, we focused on projects where we identified demand — namely, rapid passenger and cargo transportation. Moreover, by that time, it had become apparent that the investments received were insufficient to cover the entire scope of planned activities, considering the rising costs of materials and equipment, as well as other inflationary expenses not only in specific countries but also in the global economy.

As a result, we took measures that were painful for us as well — reducing the workforce of the engineering company. We fully understood that we could neither afford to pay the salaries of qualified specialists nor to develop and manufacture the high-speed product. Thus, based on the available resources and adapting to the current circumstances, we had to part with a significant number of highly skilled engineers who had been trained over several years.

We faced a choice: either we would fail to bring all three branches of the uST technology to practical implementation, or we would focus on two less costly and simpler directions to implement and launch a finished product on the transport market.

By practical implementation, I mean not test sections but real commercial projects that require the creation of certified, industry-leading high-tech complexes — not just one component of the complex, such as a uPod.

Even a certified uPod — be it a uBus, uCar, uLite, uCont, or uFlash — is of no use without the transport overpass, stations, automated control systems, energy supply, communication, and much more that make up the uST complex.

Henry Ford had it much easier: he neither sold nor developed, nor did he spend money on, other components encompassed within the concept of an "automotive complex" — such as roads, bridges, overpasses, multi-level interchanges, fuel stations, garages, repair shops (depots), automated control systems, and so forth.

We do not dwell on difficulties because we know how to overcome them, provided the necessary funding is available. This is simply a statement of facts, which we don’t need to obscure with illusions.

Let me give you a simple analogy. You cannot build a three-story house (representing the three industry-defining technologies: rapid passenger, rapid cargo, and high-speed) if there are only enough bricks, cement, and funds to pay workers for two stories. Or perhaps we should leave an unfinished building that benefits no one, including investors? What’s wrong with putting a roof over the two completed stories and earning revenue from them?

Afterward, we can construct another house, in a location where there is suitable land and funding. With the support of only the "old" investors who have been backing the project for many years, it would take us over 20 years to accumulate the funds needed for constructing a high-speed hub — approximately $750 million USD. Especially considering additional costs such as marketing expenses for investment platforms. These expenses are unavoidable, as their activities and functions also need to be funded. Without them, how would people learn about uST technology and support the creation of a new transportation industry?

Let me reiterate the areas of responsibility. The engineering company Unitsky String Technologies Inc. focuses on the development and implementation of string technologies. The investment platforms — Sky World Community and RSW-Systems, which form a socially-venture ecosystem — are responsible for raising funds for the projects.

We guarantee that 100% of the funds received by Unitsky String Technologies Inc. are used for their intended purposes. For all 10 years of its existence, the company has operated strictly within the legal framework, meticulously adhering to laws. Every year, Unitsky String Technologies Inc. undergoes a financial audit, the results of which are published on the company’s website for public access.

I have often mentioned that I am not just an engineer-inventor, designer, and scientist. I am also a businessman, entrepreneur, and manager who knows how to handle money, values its worth, and understands how to manage investments correctly to maximize benefits. I know how to minimize risks in force majeure situations as well. In fact, for many years — if not decades — I have been working as a crisis manager.

And I have the necessary experience to do this. I began building it back in the late 1980s, when I was creating various business structures: trade, construction, production, research, and agricultural enterprises where more than 30 of my inventions were practically implemented. By the way, some of these enterprises are still operational and continue to generate profits for me as their founder.

From the profits generated by these companies, I personally invested over $10 million USD into the development of string transport. Therefore, contrary to what some detractors attempt to suggest, I was neither a poor nor an unrecognized engineer. If that were the case, would anyone want to support a string transportation project? Would so many people believe in the ideas of a nameless and poor inventor?

This is far from the truth. I am the largest financial investor in uST technology, excluding the intellectual property I contributed, which has been independently valued at $400 billion USD by an expert appraisal company.

This intellectual property is also an investment. Without my contributions, what has been achieved so far would not have been possible.

We are all in the same boat. Like all other investors, I am equally interested in generating revenue from these projects as soon as possible.

Having carefully analyzed the situation, including all risks and opportunities, we made a pivotal strategic decision: to direct key resources toward the development of rapid passenger and cargo transportation systems.

Thus, all available resources — both human and financial — were focused on the phased development of uST technology. Efforts were conducted within urban speed limits of up to 150 km/h. This deliberate and systematic approach not only validated the viability of uST technology but also facilitated all the necessary work required to achieve the ultimate goal: the swift commencement of commercial projects.

I have repeatedly stated in previous interviews that we are creating a technology that forms the backbone of an entire industry. Our product demands not just the development, manufacturing, testing, and certification of a range of rolling stock models — as car manufacturers have done. It also requires designing, building, and certifying fundamentally new overpass-type roads, complete with logistical, energy, and accompanying infrastructure above the ground.

Over the years, even while primarily focusing on rapid passenger and cargo solutions, we had to undertake an extensive array of complex tasks. This included developing, manufacturing, testing, and certifying four intricate systems of uST technology from scratch: the string rail overpass, automated control systems, steel-wheeled electric vehicles, and the accompanying logistical overground infrastructure.

Additionally, we’ve established industry-defining elements, such as demonstration and testing centers in Belarus and the Emirates, our own high-tech production facilities, and an engineering school spanning scientific, design, engineering, and manufacturing expertise — all achieved through the efforts of a single small engineering company.

Over the preceding years of hard work, we have developed, tested, and implemented 15 fundamentally different models of uPods, 7 types of pre-stressed string rail overpasses, 10 passenger stations integrated with anchoring structures, and two central dispatch centers.

We also developed and tested an automated control system. Furthermore, we introduced complex overground infrastructure objects within uST complexes: stops, traction substations, communication lines, energy supply systems, repair workshops (depots), loading and unloading terminals, and switch junctions.

Over this period, we achieved certification for new, previously unexplored transport vehicles, and implemented overground construction structures:

But we didn’t stop at designing, conducting expert evaluations, and constructing them — we went further and brought everything into operation.

Imagine the scale of work undertaken, including scientific research, project estimates, and documentation! Each vehicle alone requires around 5,000 blueprints!

Keep in mind, all engineering and technological solutions undergo approval by state organizations to ensure compliance with current standards and regulations. Consider how much time it often takes to obtain routine certificates or documents. And here we’re talking about the certification and standardization of a new, industry-defining product — one that, I emphasize again, has never been developed or tested before.

It’s worth highlighting that uST transport and infrastructure complexes have undergone tests and demonstrated functionality in two climatic zones, which now allows us to present ready-made solutions for tropical countries as well.

Today, with tested and validated solutions at speeds up to 150 km/h, we are advancing commercial projects across nearly all continents.

The attached tables provide a detailed overview of the extensive work carried out on rapid passenger and cargo solutions. Specifically, they cover the four key components of uST transport and infrastructure complexes: rolling stock, string rail overpasses, automated control systems, and overground infrastructure equipped with energy supply systems. These tables also allow for a comparison showing how smaller scale of work completed on the high-speed complex is, in contrast to the developments of uST rapid passenger and cargo systems with speeds of up to 150 km/h.

High-speed technology is a promising yet immensely complex transport and infrastructure product to implement. It follows specific development stages and has its own life cycle, with each phase requiring thorough and meticulous work. Firstly, the high-speed project is groundbreaking, making it crucial to understand that the cost of any mistake is human lives. Secondly, specialized research on an infrastructure site with a land area of at least 25 km is required.

As I mentioned in a previous interview, the high-speed direction is also highly cost-intensive. According to our estimates, its full creation and development will require approximately $750 million USD, and even more when considering associated costs.

Ten years ago, when we began operations in Belarus, this very project would have required only $200-250 million USD. However, over the years, the prices for materials, structures, and equipment have increased significantly. For example, the price of one type of equipment essential for our work has risen from $3 million to $10 million USD.

Considering the importance, responsibility, and expenses involved in the development of the high-speed branch, we have only recently fully developed the necessary competencies and are now prepared to transition to full-scale work. Naturally, the experience gained from developing simpler rapid passenger and cargo solutions will help accelerate the progress of the more complex high-speed direction. Nevertheless, the work we have managed to accomplish so far on high-speed technology represents just a drop in the ocean.

At the same time, I would like to remind you that the engineering work that Unitsky String Technologies Inc. specialists will carry out on the high-speed direction in the United States will constitute a commercial order, generating revenue for the company. If we estimate the project’s cost at around $750 million USD, at least $150 million (or potentially more) will be allocated to the UST Group of Companies for project-related work, manufacturing of rolling stock at SW Plant, special operations, author’s supervision, and other associated services.

This will represent a significant additional income stream alongside the revenue generated from commercial projects focused on rapid passenger and cargo solutions, which we are actively working on at present. Altogether, these efforts will accelerate the achievement of key performance indicators necessary for expediting investor payouts.

— Anatoli, what has actually been done so far in the high-speed branch?

— As I mentioned in my previous interview, the development of uST high-speed technology has now reached the stage of conceptual elaboration of the main structural components.

First of all, a working model of the high-speed uPod — uFlash — was developed. However, uFlash was not fully implemented. The traction module (mule) was presented and tested separately, and the interior part was shown separately. Moreover, in our case, the traction module (mule) was specifically designed as a test unit to refine future directions rather than as a fully completed solution. Most systems, components, and assemblies require further refinement, and some are missing altogether. It should also be remembered that this is just a prototype of one of the possible and simplest family-type models with six seats.

A full-fledged demonstration of uST high-speed technology requires the development of an entire lineup of rolling stock — high-speed public passenger, cargo, as well as cargo and passenger uPods, primarily trains. Absolutely everything in these high-speed uPods will differ from urban uBuses. It is similar to how a city tram differs from complex and high-tech high-speed trains.

At the EcoTechnoPark Testing Center, we have implemented a test track of less than a kilometer in length — a truss-type test track.

Under favorable circumstances, we had planned to use this overpass as the initial acceleration section for uFlash. However, it did not work out, as we were not granted the 25 km of land (as I mentioned earlier).

I would also like to point out that this truss-type test track is a first-generation version, which was primarily needed for technology testing. This version had all the so-called “teething problems”, which we have since outgrown.

In any case, given the limited length of the acceleration section, which was insufficient for reaching cruising speed and subsequent standard braking, we would not have been able to exceed 80 km/h in testing. When increasing speed to the target 500 km/h, the challenges will be entirely different, as conditions and loads will fundamentally change. This applies to everything: braking at 500 km/h, current collection at 500 km/h, ensuring a smooth ride, and so on. These are completely different challenges compared to those we have already solved for speeds up to 150 km/h.

What needs to be designed for the high-speed hub in the U.S. will be entirely different — different string rails, different supports and support nodes, etc. The high-speed motor wheels of rail electric vehicles will also be completely different, as will their high-speed bearings, which are not manufactured in Russia or Belarus.

— Anatoli, what intellectual property was transferred to GTI?

— Intellectual property was transferred to GTI — namely, the know-how of the “string rail transport system” technology, which assessed innovative solutions for overground cargo and passenger transportation, including high-speed applications.

However, it is important to understand that the high-speed technology was only partially evaluated in this context — specifically regarding potential material savings in the construction of the string rail overpass.

Let me emphasize again: the assessment of the transferred intellectual property did not go beyond potential cost savings. A significant portion of the intellectual property related to the high-speed branch, particularly concerning the aerodynamics of the high-speed rail uPod, was not transferred to GTI.

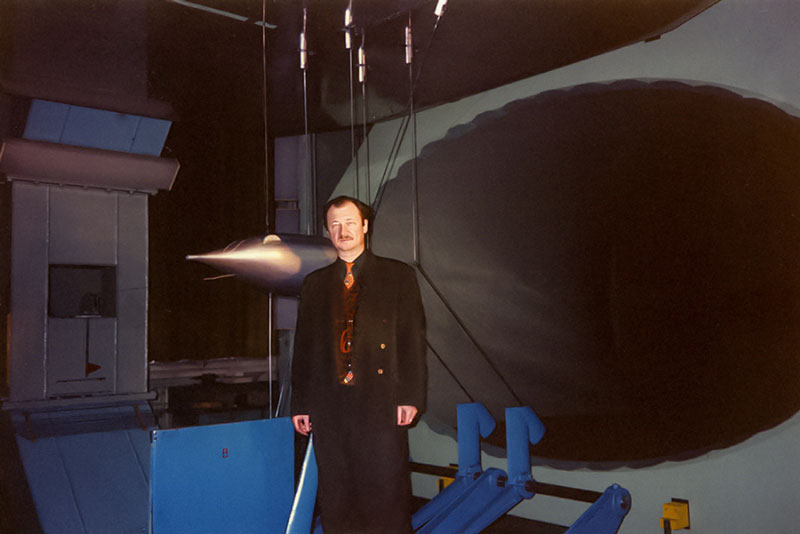

I have been developing aerodynamics, as a separate technology, over the course of 20 years and it was only recently properly evaluated by experts. For a long time, I personally funded a vast amount of independent work, the first results of which were published in 1995 in my monograph String Transport Systems: On Earth and in Space. Over more than two decades of research and development in the aerodynamics of the high-speed rail electric car, this vehicle was tested in a large aerodynamic tunnel in St. Petersburg dozens of times.

Despite the fact that this development process took decades, aerodynamics — as a core component of high-speed string transport technology — was recognized as intellectual property (know-how) only recently. Therefore, I will repeat once again: this intellectual property was not transferred to GTI.

The maximum speed of a high-speed vehicle depends primarily on aerodynamics rather than on the wheel, the smoothness and oscillation dynamics of the track, or the “wheel–rail” contact. Aerodynamics encompasses a whole range of developments forming the foundation of the high-speed direction, without which it simply cannot exist. For example, working on aerodynamics involves solving critical challenges such as calculating lift distribution, reducing aerodynamic noise, determining geometric parameters, optimizing the shape of body elements, ensuring airflow access to units and systems, and much more.

— Anatoli, why is the work on the high-speed direction so complex?

— We are developing an industry-defining technology. This ambitious endeavor requires an immense amount of highly complex work. Once again, I want to emphasize that the high-speed uPod is just a small part of the high-speed transport and infrastructure complex.

The uST high-speed complex includes:

Behind this list of necessary developments lies the immense scientific complexity, engineering challenges, and costs of the innovative work still ahead. Designing a string rail is far more difficult than a conventional railway track. This complexity applies not just to high-speed aerodynamics but to every component. Even the wheel of a high-speed rail electric car, the current collector, the track switches, the anti-derailment system, and the automated control system will be an order of magnitude more complex than everything we have developed over the past 10 years.

To optimize financial resources and avoid unnecessary expenditures, the development and certification of high-speed solutions require extensive research into the various systems and subsystems of the uST high-speed complex — there are dozens of them. This has a significant impact on the funding of high-speed solutions, including the development of specialized materials that ensure the required strength, reliability, and durability of structures, not only in static conditions but also under the dynamics of high-speed travel.

Let me give a couple of examples of how much time and money other companies have spent on transportation projects. The development of the Transrapid magnetic levitation train cost Siemens and Germany €6.5 billion and took 50 years. Or look at Mercedes: developing just one Mercedes Actros truck (without working on highways, transport logistics infrastructure, or an automated control system) required €1 billion and more than 8 years. And that was with a team of 1,800 specialists dedicated solely to a single truck model! We have never had, and still do not have, such a large team, such financial resources, or that much precious time.

A rhetorical question: are we working slowly, or are we actually moving at an incredibly fast pace, given the scale and complexity of our industry-defining technology?

Skeptics might see this as complaining about engineering difficulties, a lack of time, and financial constraints — thinking, “Give us another billion dollars or euros and another ten years, and maybe something will come of it.” No, this information is shared for a completely different reason: investors need to understand the innovative field we are dealing with.

Now, let me briefly outline the specifics of working on the components of the uST high-speed transport and infrastructure complex.

Rolling Stock

A high-speed uPod train is no less complex than a long-haul aircraft. For example, it took approximately 10 years and around $10 billion to develop the Superjet. And for many years, they have continued to make modifications and improvements.

Just like an aircraft, a high-speed uPod consists of thousands of components and assemblies — from bolts and nuts to copper wires and rare-earth magnets in the motor wheels — along with tens of kilometers of wiring and electrical cables.

Take the motor wheel, for instance. It contains hundreds of meters of specialized wires in the stator coils and hundreds of rare-earth magnets of a unique configuration, placed in specially designed rotor slots. Moreover, this motor wheel must be specifically designed for a high-speed uPod, delivering high power — over 100 kW — along with high rotational speed and torque. This is an extremely complex piece of electrical engineering!

The structural frame of a high-speed uPod must be aerodynamic, strong, durable, and lightweight, just like the frame of a long-haul aircraft. Developing such a frame also demands significant time and financial investment. Then there is the drive system and bogie — the most critical, complex, and expensive elements of a high-speed train.

String Rail Overpass

The high-speed string rail we plan to demonstrate is entirely different from the rails used in the rapid passenger and cargo systems in Belarus and the UAE. To put it into perspective, the high-speed switch required here — about 500 meters long — is an extremely complex piece of equipment, without which the high-speed system cannot exist.

Current Collector

At a speed of 500 km/h, efficiently collecting power from the contact rail is critical, as conventional railway standards do not apply to our system. In fact, current collection is one of the biggest challenges faced by high-speed train developers.

Since high speeds demand significant energy consumption, battery-powered or onboard energy sources are not an option. This makes it necessary to develop and test a specialized current collection system for the high-speed uPod.

Power must be transferred from the rail to the wheel. At a rolling speed of 140 m/s, the contact line is constantly shifting, altering the path of charged particles to the collector brushes. Any dust, snow, or debris can affect the stability of the contact and energy transfer.

Factors such as speed, contact voltage, suspension performance, wind, rain, snow, dust, and extreme temperatures all contribute to inconsistencies that cannot be fully predicted in theoretical models. This is why real-world testing at high speeds is essential — each of these challenges requires dedicated research, which involves significant financial and time investments.

Overground Infrastructure

There is also the high-speed overground infrastructure, which includes stations, terminals, cargo hubs, transfer nodes, maintenance workshops (depots), and much more. All of this must be designed, built, tested, and then submitted for state expertise and certification.

Certification

Add to this the certification process — not just for a single vehicle or aircraft, but for an industry-defining product with all its components:

What I have outlined is only a fraction of the challenges we still need to solve in the further development of the uST high-speed transport and infrastructure complex.

I hope I have answered the key questions regarding the development of our high-speed branch. We can continue discussing the specifics of string transport development in future interviews.

This form asks for your consent to allow us to use your personal data for the reasons stated below. You should only sign it if you want to give us your consent.

Who are we?

The name of the organisation asking you for consent to use your information is:

Global Transport Investments

Trident Chambers, P.O. Box 146, Road Town

Tortola

British Virgin Islands

We would like to use the following information about you:

Why would we like to use your information?

Global Transport Investments would like to send this information to company registry, inform you about its news, for refund purposes.

What will we do with your information?

We store your name, address, ID Data, date of birth into company registry. We will share your e-mail & phone number with IT Service (https://digitalcontact.com/), SMS Center (http://smsc.ru). They will add your details to their mailing list and, when it is news update, they will send you an email or sms with details. We store your credit card number for possible refunds.

How to withdraw your consent

You can withdraw the consent you are giving on this form at any time. You can do this by writing to us at the above address, emailing us at the address: [email protected] or by clicking on the unsubscribe link at the bottom of emails you receive.

This privacy notice tells you about the information we collect from you when you sign up to receive our regular newsletter via our website. In collecting this information, we are acting as a data controller and, by law, we are required to provide you with information about us, about why and how we use your data, and about the rights you have over your data.

Who are we?

We are Global Transport Investments. Our address is Trident Chambers, P.O. Box 146, Road Town, Tortola, British Virgin Islands. You can contact us by post at the above address, by email at [email protected].

We are not required to have a data protection officer, so any enquiries about our use of your personal data should be addressed to the contact details above.

What personal data do we collect?

When you subscribe to our newsletter, we ask you for your name and your email address.

Why do we collect this information?

We will use your information to send you our newsletter, which contains information about our products.

We ask for your consent to do this, and we will only send you our newsletter for as long as you continue to consent.

What will we do with your information?

Your information is stored in our database and is shared with with IT Service (https://digitalcontact.com/), SMS Center (http://smsc.ru). It is not sent outside of the Euro. We will not use the information to make any automated decisions that might affect you.

How long do we keep your information for?

Your information is kept for as long as you continue to consent to receive our newsletter.

Your rights over your information

By law, you can ask us what information we hold about you, and you can ask us to correct it if it is inaccurate.

You can also ask for it to be erased and you can ask for us to give you a copy of the information.

You can also ask us to stop using your information – the simplest way to do this is to withdraw your consent, which you can do at any time, either by clicking the unsubscribe link at the end of any newsletter, or by emailing, writing us using the contact details above.

Your right to complain

If you have a complaint about our use of your information, you can contact the Information Commissioner’s Office.

Rate and Comment

You can assess the importance of a particular publication and the level of its preparation. Share your opinion in the comments!